Life Cycle Assessment of Aircraft Interior

For my Joint Interdisciplinary Project at TU Delft, undertaken in collaboration with Collins Aerospace, I evaluated the environmental impact of aircraft cabin interiors through a detailed life cycle assessment (LCA). The project combined sustainability analysis and engineering reasoning to guide material substitution for next-generation seating products. Working in an interdisciplinary team of aerospace, mechanical, and management students, I acted as the technical lead—bridging fuel burn modeling, emissions accounting, and environmental interpretation—to quantify how material choices shape the carbon footprint of aircraft interiors.

Why Sustainable Cabin Design Matters

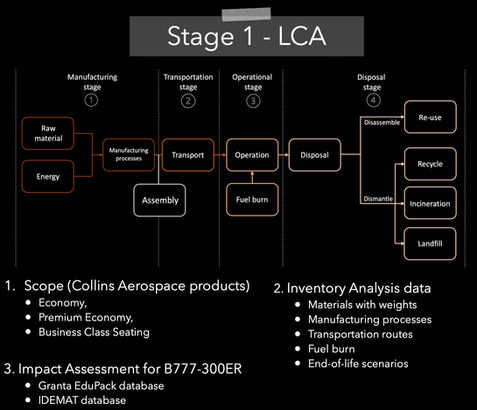

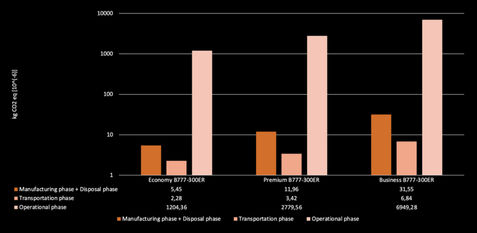

As airlines aim for net-zero targets by 2050, improving cabin sustainability offers tangible pathways to reduce lifecycle emissions without requiring radical airframe redesigns. Our project addressed an especially relevant challenge for Collins Aerospace: understanding how frequent cabin reconfigurations (every 4–7 years) affect the environmental footprint of their seating products. Using data for economy, premium economy, and business class seats on a various aircraft, we modelled cradle‑to‑grave emissions, capturing the manufacturing, transportation, operation, and disposal phases. The results confirmed that the operational stage—driven primarily by fuel consumption linked to seat mass—dominated, contributing over 99% of total CO₂ impact. This finding established a strong foundation for focusing on lightweight design as the most effective strategy for emission reduction.

Assessing Life Cycle Impacts Across Seating Classes

To generate accurate results, we extracted data from thousands of engineering drawings of seating assemblies, cataloguing material compositions, weights, and manufacturing details across classes. These inputs fed into an Excel-based model referencing verified databases such as Granta EduPack and IDEMAT. Each life cycle stage—manufacturing, transport, operation, and end‑of‑life—was characterised using kg CO₂ equivalent impacts, visualised in a comparative bar chart showing phase contributions for different seat categories. Even small design differences revealed measurable performance gaps once scaled to the fleet level. I designed this systematic approach to ensure that Collins could trace environmental hotspots not only across materials but also across cabin configurations.

Automating Data Extraction and Emission Modelling

The data collection process initially proved tedious—many of the engineering drawings existed only as image-based PDFs with embedded text. To accelerate progress, I proposed and implemented a Python-based Optical Character Recognition (OCR) script to automatically extract material, weight, and process data into structured spreadsheets. This automation saved the team significant manual effort, enabling us to expand the scope of the assessment to include future propulsion scenarios. Building on that foundation, I also developed a fuel burn model linking seat mass reductions to operational CO₂ savings over different mission lengths. This data-driven workflow not only improved accuracy but also allowed us to quantify how design changes translate directly to climate and cost impacts.

Material Substitution and Future Scenarios

We explored alternative configurations where 80% of aluminium alloys were replaced with carbon‑fibre‑reinforced polymers (CFRP) and steel with titanium—measuring knock‑on effects across manufacturing, operation, and disposal. While production and disposal emissions increased slightly due to composite processing, operational savings far outweighed them: overall carbon foot reductions averaged 15% over five years. Beyond immediate comparisons, we extended our analysis to emerging propulsion systems, modelling future aircraft powered by sustainable aviation fuels (SAF), hydrogen, and electric engines. The scenarios demonstrated that hydrogen‑fueled operations could reduce total emissions by nearly 90%, with lightweight interiors amplifying those gains even further. Visual outputs—including process flow diagrams and cumulative emission plots—captured how integrative design thinking can future‑proof aircraft sustainability strategies.

This project demonstrated how lifecycle thinking can transform engineering decisions from reactive assessments into proactive design strategies. Working as the only aerospace engineer in an interdisciplinary team, I combined emissions modelling, automation, and materials analysis into a coherent framework that guided actionable sustainability recommendations for Collins Aerospace. The process not only earned a 9.0/10.0 academic distinction but also reinforced my conviction that sustainability in aviation must begin in the design studio—where small, intelligent changes can achieve measurable impact across fleets and decades of flight operation.