Multidisciplinary Design Optimisation of a Boeing 737 Wing

For my university course project, I collaborated with a teammate to conduct a multidisciplinary optimisation of the Boeing 737-600 wing at the conceptual design phase. We integrated aerodynamic, structural, loads, and performance solvers that communicated iteratively, allowing the wing shape and design variables to evolve autonomously toward a more efficient configuration. This process led to a 10% reduction in fuel consumption for a fixed mission by balancing complex trade-offs across engineering disciplines, highlighting how coordinated computational tools can drive significant improvements in aircraft design without manual intervention.

Problem Statement and Constraints

The project’s goal was to reduce fuel consumption indirectly by minimising the maximum take-off weight (MTOW) for a fixed mission, while applying two practical constraints to ensure a realistic and safe design. The fuel volume was limited to the tank capacity available in the wing, preventing the optimisation from suggesting fuel loads that simply would not fit in a real wing. Meanwhile, the wing loading—defined as the force per unit wing surface area—was restricted to stay below the reference wing’s value to maintain safe structural limits and predictable flight behavior. These constraints were especially necessary because the low-fidelity aerodynamic, structural, and loads solvers used are simplified versions of the complex physics governing real wings. Such simplified models can be prone to exploitation by the optimisation process through unrealistic configurations if left unconstrained. By enforcing these simple yet essential boundaries, the optimisation process could freely adjust wing shape and design variables within safe and feasible limits to find the most efficient design.

Intelligent Parametrisation Strategy

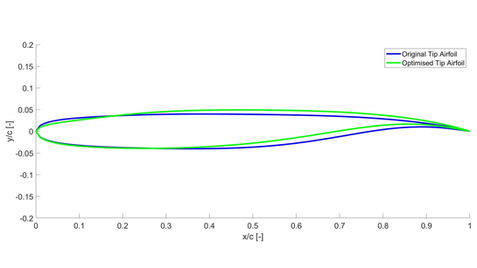

To explore wing geometric variations efficiently, I parametrised the airfoil shapes at the root and tip using Bernstein Coefficients. Without this parametrisation, each coordinate of the airfoils would have represented a design variable that would have added additional information the optimisation needs to vary and evaluate, which is then passed between solvers at every iteration. Using raw coordinate points would, therefore, have meant handling a much higher number of variables, increasing computation time and complexity. By approximating complex airfoil curves with far fewer Bernstein Coefficients, we reduced redundancy and computational load, accelerating solver communication and convergence while retaining accurate representation of the aerodynamic shape. This strategic parametrisation balanced the design flexibility with efficient optimisation performance.

Optimisation Outcomes and Design Improvements

The optimisation resulted in a 9.7% reduction in fuel consumption, demonstrating how even small geometric adjustments can make a major difference in aircraft performance. Since a Boeing 737 must fit into standard airport hangars, we restricted the wingspan during optimisation, pushing the solver to find efficiency gains elsewhere. It did so by slightly reducing chord lengths—the width of the wing from leading to trailing edge—and increasing the outer sweep, giving the wing a more streamlined, higher-performance shape. These changes allowed the lift to be distributed more evenly along the wing, reducing wasted energy from drag. Subtle refinements to the airfoil shape, such as smoother leading edges and gradual twists, further improved aerodynamic balance, collectively contributing to the aircraft’s reduced fuel burn.

Conclusions and Critical Reflection

The optimisation converged to a stable, high-quality solution, showing that the design had reached its best possible state within the given constraints. We confirmed this by applying the Karush–Kuhn–Tucker (KKT) conditions—a mathematical check that examines the gradients of the objective and its constraints. In simple terms, it ensures that every constraint pushes back against further improvement, meaning no direction exists where performance can increase without breaking a rule. The solver met all these conditions flawlessly, validating the result while achieving nearly a 10% reduction in fuel use. It was a powerful demonstration of how physics, computation, and mathematical logic can combine to reveal the limits of aerodynamic efficiency.

This project showcases how multidisciplinary optimisation brings together aerodynamics, structural design, and performance analysis into one cohesive framework—each discipline influencing and responding to the others. It demonstrated how small design adjustments can ripple across multiple systems, revealing trade-offs that wouldn’t be visible in isolated analyses. Working through this process strengthened my ability to connect theoretical modelling with practical engineering decisions, sharpened my analytical thinking across different domains, and reinforced my passion for advancing sustainable aircraft design through data-driven innovation and collaboration.