Automation of CAD Generation of Turbine Rear Structure

For my internship project in the Knowledge Based Engineering course, I automated the design of a Turbine Rear Structure (TRS) for GKN Aerospace. This project combined practical engineering tasks with automation to improve efficiency. By translating expert design rules into a rule-based Computer Aided Design (CAD) tool, I demonstrated how manual modeling could be accelerated while ensuring design integrity.

Why Automate TRS Design?

Traditionally, Turbine Rear Structure (TRS) models for aircraft engines required days of manual CAD work, slowing production and consuming engineering hours whenever a new engine variant with small diameter or geometry tweaks was needed. This project aimed to shift that paradigm by automating TRS generation so dimensional changes—input/output diameters, vane counts and airfoil profiles, lug placements, and other key parameters—could be produced reliably and quickly from a standard schematic. For reference, both the nomenclature of the components and the schematic of the TRS are displayed on the right. The result is a knowledge-driven CAD workflow that preserves the essential TRS architecture (shrouds, hubs, vanes, lugs, and mounting features) while enabling rapid, specification-driven geometry updates, saving considerable engineering time and ensuring consistency across engine variants.

Tackling Tricky Design Rules

Designing the TRS requires more than speed—each model must meet strict rules for flow, strength, and manufacturability. To address this, I developed internal analysis modules within the Rule Based Parametric Model of the KBE application. These modules automatically evaluate critical design parameters as soon as the user inputs data, ensuring compliance with engineering constraints.

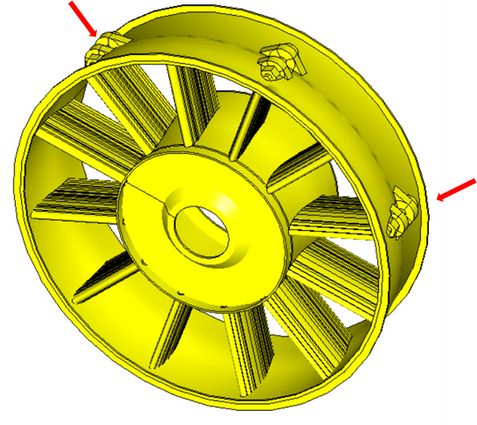

One key example is lug positioning, where lugs are aligned with vane locations, as shown on the left, to minimise aerodynamic drag by creating smoother airflow around the structure. Additionally, this also improves its structural efficiency. If vane spacing becomes too tight for proper lug placement, the program raises warnings and automatically transfers lugs to adjacent vanes, which is also shown on the left. This real-time checking and correction ensure the TRS design stays viable, replicating the judgment calls engineers make during manual reviews.

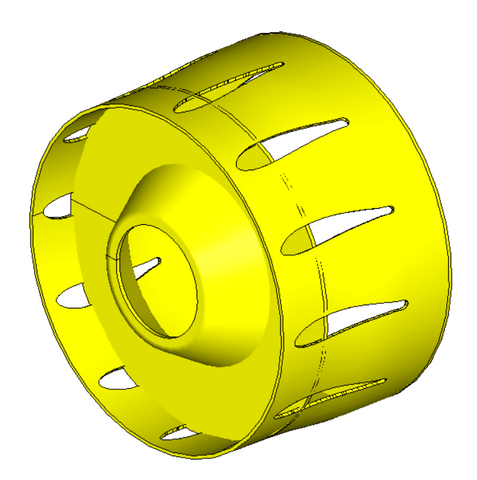

Modular Component Generation and Precise Assembly

Each major component of the TRS—the hub, shroud, vanes, and lugs (including bumps and bolts)—was generated separately within the KBE framework, as shown on the right. During assembly, careful attention was given to prevent component intersections or gaps, maintaining the extremely tight tolerances necessary for manufacturability and structural integrity. I also designed the system so that components could exchange key geometric information; for example, the hub geometry was adjusted to include cutouts matching the airfoil profiles of the vanes. This interconnected, parametric approach ensured a cohesive, manufacturable assembly that respected both individual part specifications and overall system integration.

Bridging CAD and Real-World Analysis

I made sure that the generated TRS components could seamlessly transition from design to analysis. After creating the geometry, I set up automatic export options to save files in STEP format and prepare mesh-ready files for external tools, as shown on the left. This enabled teams to quickly and reliably perform strength and thermal analyses in software like ANSYS, supporting a complete workflow from design to validation.

This project exemplifies how methodical engineering automation can radically improve efficiency and reliability in aerospace component design. By integrating knowledge capture, parametric modeling, rule-based validation, and simulation readiness, it demonstrates initiative and technical depth in developing scalable solutions for complex tasks. The figures throughout illustrate the step-by-step approach and the finished TRS assemblies that emerged from automated logic and hands-on engineering. The workflow supports both speed and rigor—helping engineers focus their time and talent where it matters most, advancing automated KBE applications as essential tools for next-generation aerospace engineering.

Location

Delft, The Netherlands

Project Type

Internship / Coursework

Date

March 2022 - June 2022

Link

Report